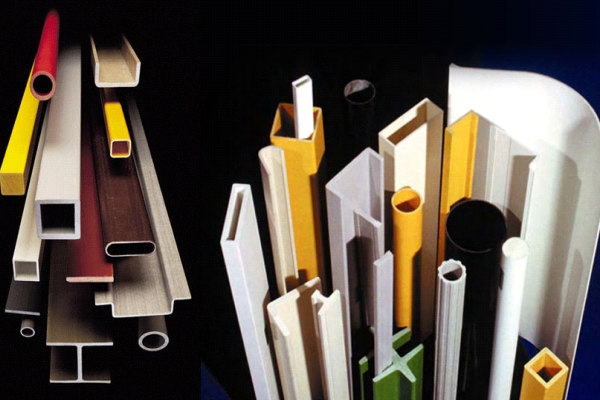

Composite / Light Weighting

Today, companies must abide by new increasingly stringent environmental regulations. OEMs have to undertake to reduce the carbon footprint of their vehicles. To fulfil this requirement, APPL global supports the automotive, railway, defence & aerospace industry, by developing high performance thermoplastics as substitutes to metal. The objective: to reduce the weight of structures and therefore help minimize their fuel consumption