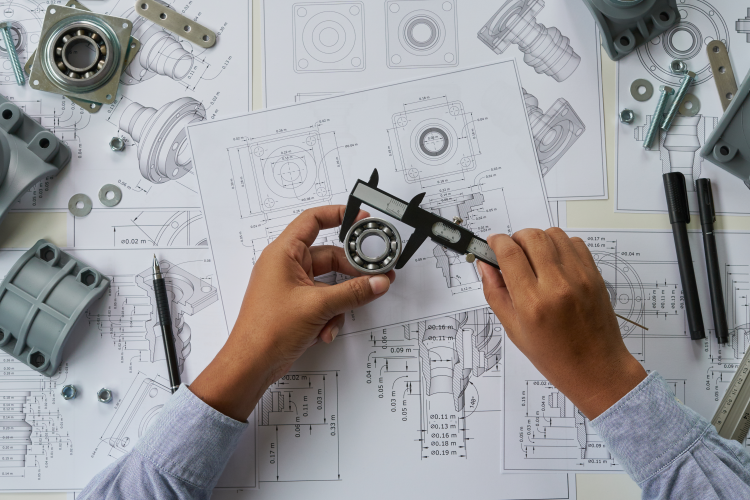

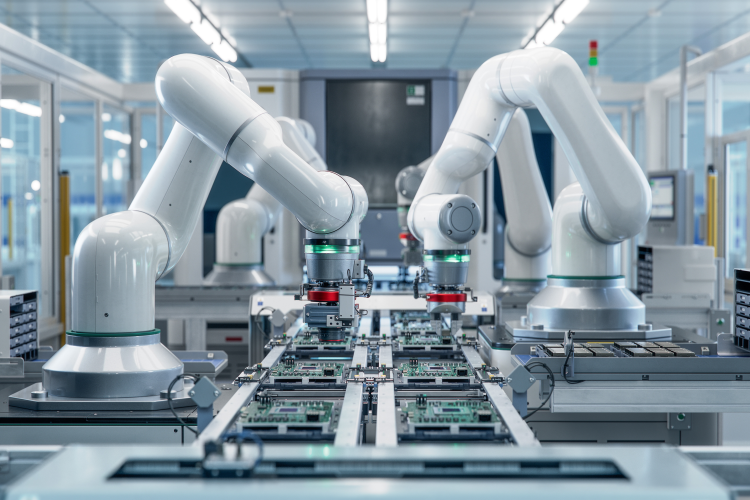

Globally, advanced manufacturing processes are undergoing a significant transformation with a key emphasis on optimizing throughput, minimizing intra- and inter-workspace logistics, and enhancing operator safety. APPL Global employs a holistic approach, integrating product, system, and functional strategies to deliver cutting-edge manufacturing solutions. Our manufacturing engineering services encompass CNC programming, process planning, assembly engineering, tool design, along with should-cost analysis, prototype development, and first article inspection.

Through collaboration with APPL Global’ s manufacturing engineering consultants, our clients have successfully optimized their total cost of ownership, increased manufacturing output, minimized process lags, and achieved their operational objectives.