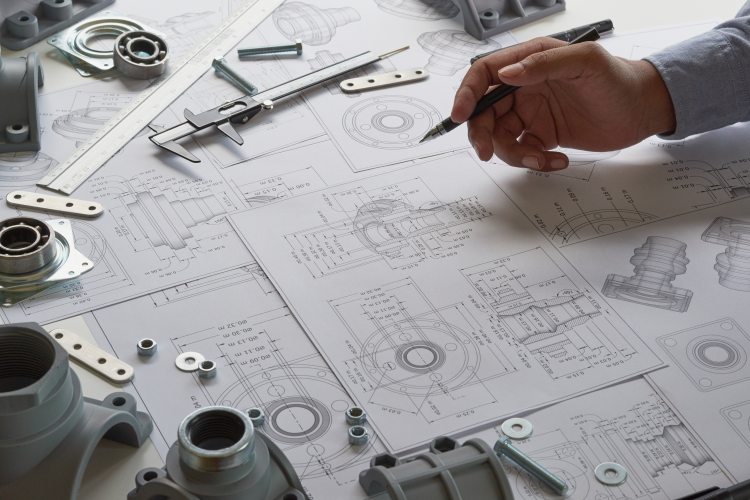

APPL Global Infotech brings extensive experience in industrial plant design spanning the power, mining, and oil and gas sectors. We provide swift mobilization and comprehensive plant engineering services to address the most crucial challenges.

Our design engineering services encompass the entire plant lifecycle, covering front end engineering design (FEED), detailed engineering, and field services support. We leverage digital industrial plant design technologies aligned with regulatory standards and compliance requirements to enhance operational efficiency and unlock new profit opportunities from existing assets.