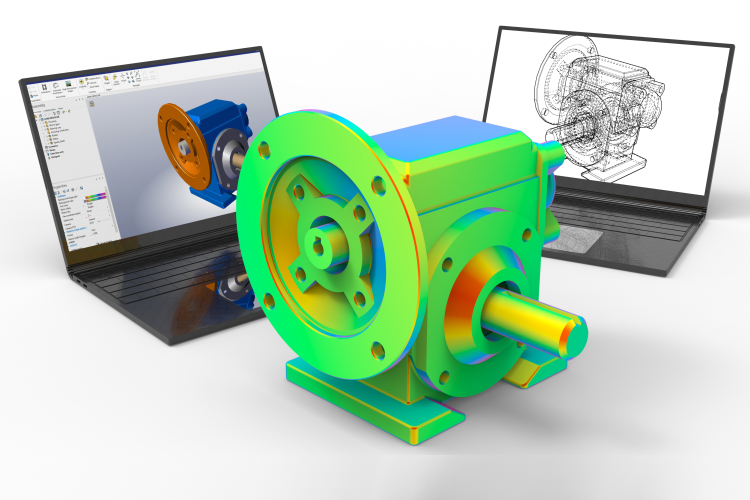

The mechanical engineering industry faces a crucial need for reinvention due to escalating product costs and margin pressures. To stay competitive, it is essential to shift beyond traditional engineering methods, amplify efforts in research and development, harness new technologies, and facilitate swifter, superior, and more cost-effective product development.

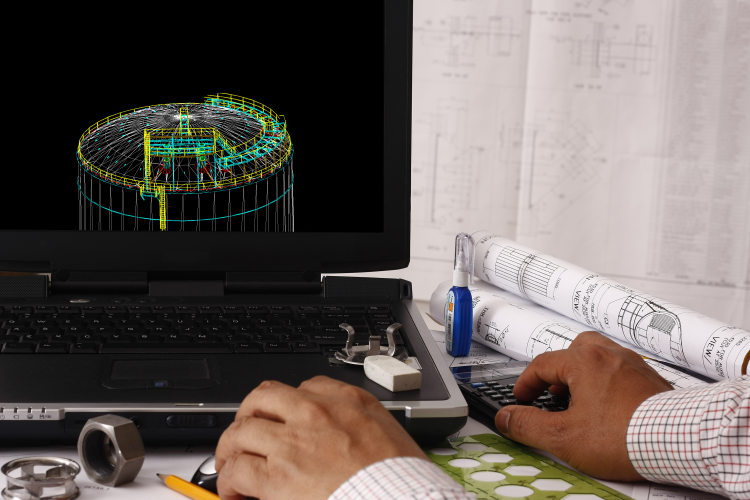

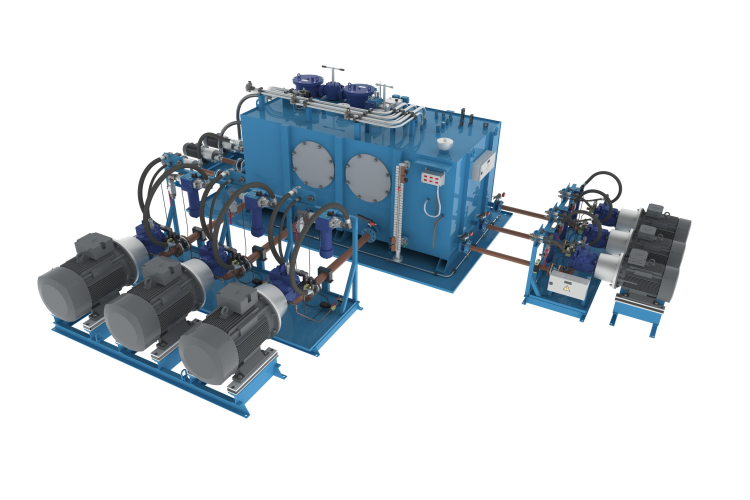

For over a decade, APPL Global Infotech has been a trusted collaborator with businesses, providing cutting-edge mechanical engineering services. Armed with a solid foundation in mechanical engineering design and specialized domain knowledge, we have successfully delivered innovative engineering solutions across a range of sectors, including energy, mining, oil and gas, healthcare, transportation, heavy equipment, consumer products, and aerospace and defence.