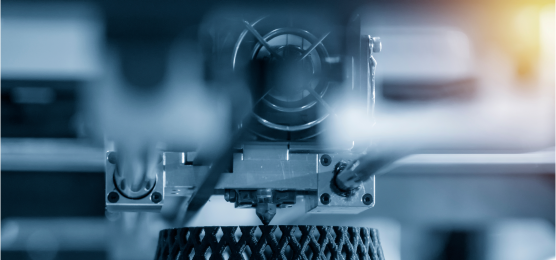

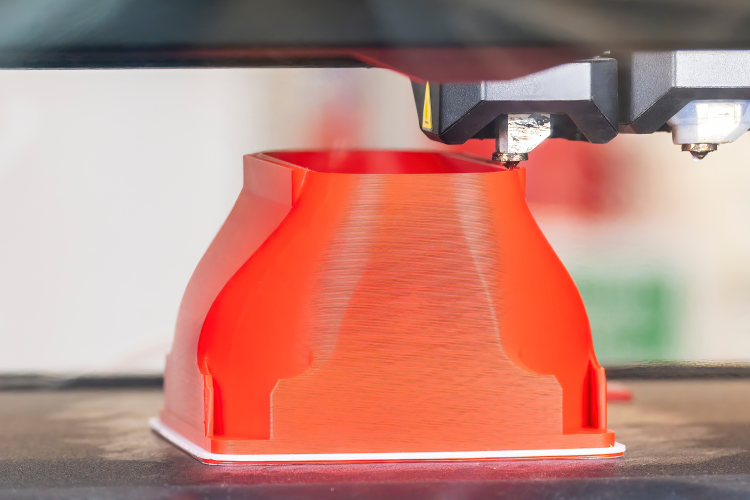

As the continuous evolution of new products remains a prevalent trend, the demand for high-quality prototypes has surged. Leveraging technological advancements and a skilled engineering team, we excel in crafting professional and top-tier prototypes. Our prototype offerings cater to diverse needs, ranging from virtual prototypes and early-stage concepts to functional demonstrations and cosmetically accurate final prototypes engineered for production.

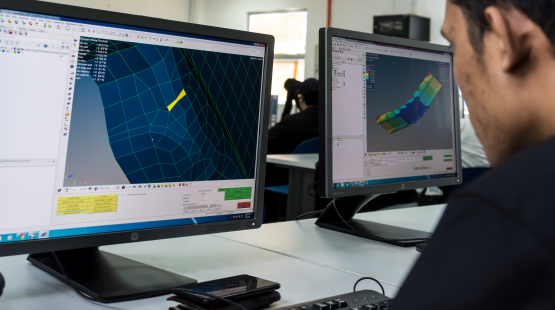

Our prototype expertise spans various domains, including Plastic Manufacturing, Metal Fabrication, and Electronic Engineering. With our team of degreed prototype engineers, we aim to bring your product to life through our four prototype options.

Upon completion of the project, all Engineering & Prototype Drawing files, along with relevant project information, are compiled and dispatched to you. Additionally, APPL Global Infotech retains a confidential in-house copy of all engineering data for your future reference. Due to the unique nature of each product, there is no standard pricing for prototyping; however, we offer free fixed-price quotes on all our Prototype Services.